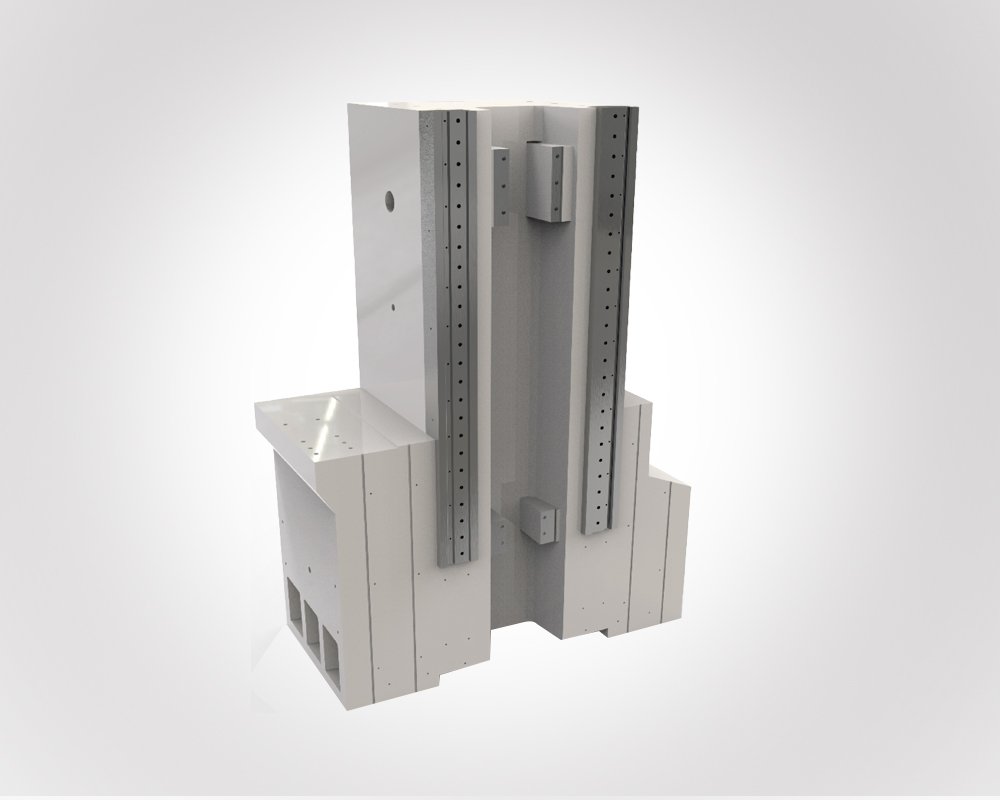

Mineral casting parts

The perpendicularity, flatness and parallelism of die components can directly reach 0.1mm. After grinding the surface of polymerized mineral materials or milling or drilling the embedded steel plate, the precision can reach 0.005mm. Especially in the production of series components, the precision surface castings produced by instrument and glue injection can greatly reduce the production cost< Br / > high performance polymerized mineral materials have high thermal capacity and have a coefficient of thermal expansion similar to that of iron. Therefore, its thermal impact on the machine bed will be weakened. This makes the ultra-high strength polymer materials well integrated with various components.

Mineral casting parts

The perpendicularity, flatness and parallelism of die components can directly reach 0.1mm. After grinding the surface of polymerized mineral materials or milling or drilling the embedded steel plate, the precision can reach 0.005mm. Especially in the production of series components, the precision surface castings produced by instrument and glue injection can greatly reduce the production cost< Br / > high performance polymerized mineral materials have high thermal capacity and have a coefficient of thermal expansion similar to that of iron. Therefore, its thermal impact on the machine bed will be weakened. This makes the ultra-high strength polymer materials well integrated with various components.

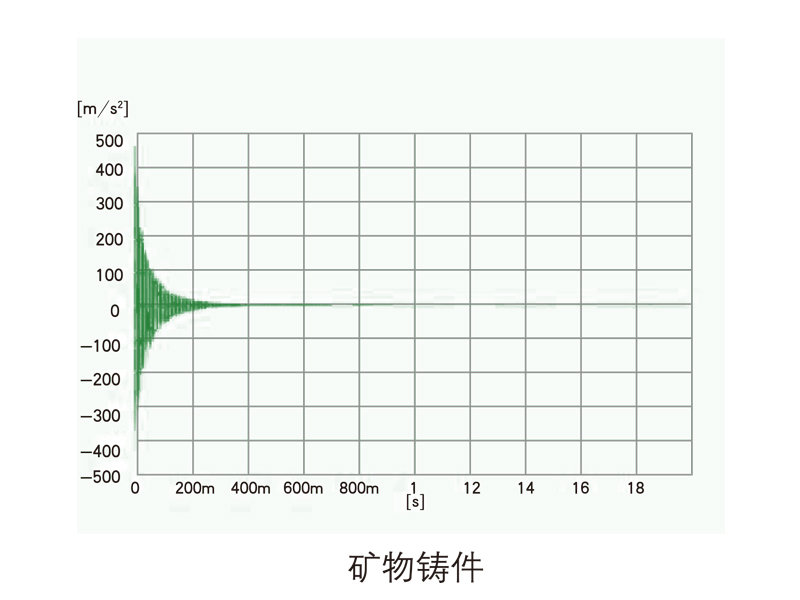

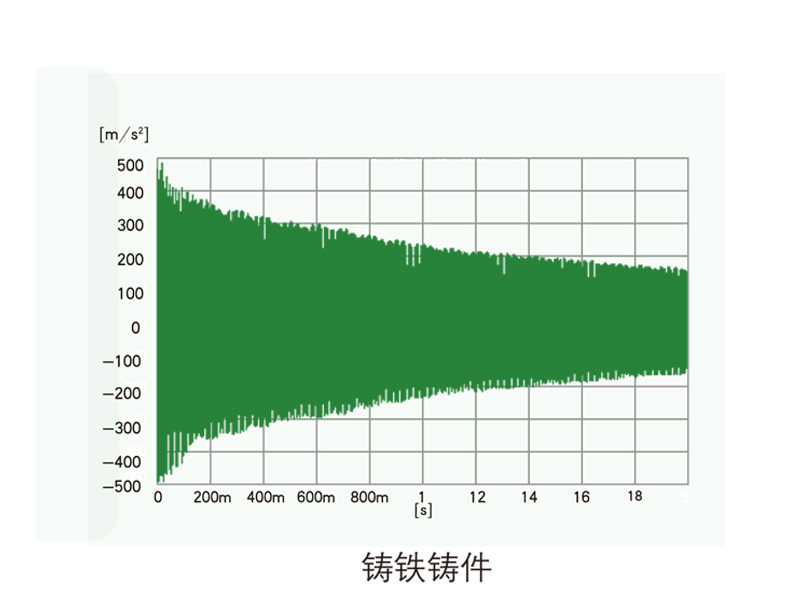

Good self compacting performance

he cementitious material with nano mineral composition has strong fluidity, so that the mineral casting material has strong self compacting performance. The whole casting process does not need to be assisted by vibration and pressure, and the casting body has better porosity and compactness< Br / > strong shock absorption performance: the damping performance of mineral castings is more than 10 times that of steel and cast iron (vibration absorption parameters), and the shock absorption capacity is better, which can greatly absorb and attenuate external vibration. In cutting, it brings excellent surface machining quality and higher machining accuracy, and increases the service life of cutting tools.

Better thermal stability

he heat conduction is 1 / 20 of that of cast iron, and the specific heat capacity is 2.1 times that of cast iron. Temperature change is one of the main reasons for the change of machine tool accuracy. Machine tool parts made of mineral castings have high specific heat capacity and low thermal conductivity, which can control the change of machine tool accuracy caused by temperature change to a low level, and ensure the stability of machine tool machining accuracy< Br / > static performance: the standard to measure the static characteristics of machine tool bed and other parts is usually the rigidity of materials, that is, small deformation under load. Under the same weight, the stiffness of iron castings and mineral castings is the same without considering the influence of shape.

High casting precision

Through accurate formwork, mineral castings can achieve casting accuracy of 0.1mm/m on the precision surface. Generally, there is no need for machining on the appearance surface, which greatly saves the processing cost and shortens the delivery cycle of castings< Br / > strong forming ability: ultra high strength polymer mineral materials have good forming ability and can complete more complex shape and structure. Bolts, gear models and machine tool models are formed from polymer mineral materials< Br / > corrosion resistance: mineral castings have good dense structure and very low porosity, low permeability, strong corrosion resistance, excellent damping performance and good wear resistance.

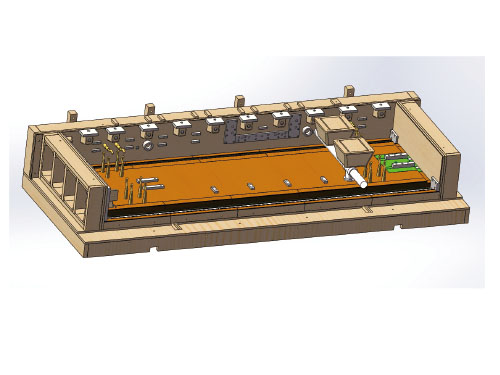

Casting Laboratory

he perpendicularity, flatness and parallelism of die components can directly reach 0.1mm. After grinding the surface of polymerized mineral materials or milling or drilling the embedded steel plate, the precision can reach 0.005mm. Especially in the production of series components, the precision surface castings produced by instrument and glue injection can greatly reduce the production cost< Br / > high performance polymerized mineral materials have high thermal capacity and have a coefficient of thermal expansion similar to that of iron. Therefore, its thermal impact on the machine bed will be weakened. This makes the ultra-high strength polymer materials well integrated with various components.

Telephone

Telephone

Products

Products

About DEED

About DEED

Contact US

Contact US