Solutions for backward production capacity

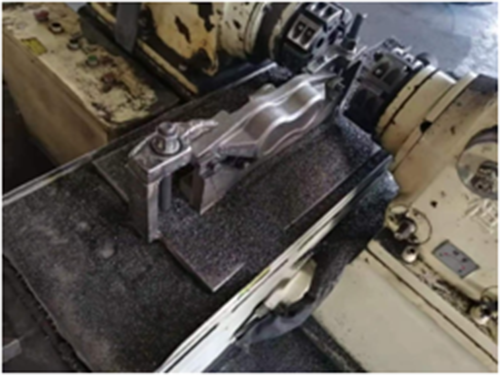

Everywhere I go, I see the following scenes. It seems that more than 20 years ago, the scene of apprenticeship can be seen everywhere. I deeply feel that the country's manufacturing industry as a whole is still relatively backward. What I know is that many of China's commercial vehicles, construction machinery and agricultural machinery industries are still processing with old and traditional process means and methods.

In 2019, the production capacity of passenger cars and trucks increased by 6.4% over last year, and the supporting enterprises for commercial vehicle parts processing grew rapidly and in a good form. The overcapacity of passenger cars has decreased from 100% in 2009 to 70% this year. There is little new production. Most enterprises are: removing capacity, reducing costs and making up for weaknesses. In 2019, the growth rate of infrastructure investment will be increased to about 10%, the growth rate of real estate investment will be slightly reduced to about 7%, and the length of construction machinery will be fast. However, supporting suppliers in commercial vehicles, construction machinery and agricultural machinery industries generally have the following problems:

1. Low production efficiency and high cost;

2. If it is done in batch, the processing quality is unstable and the precision is not high;

3. High labor intensity and many processing personnel;

4. Frequent processing turnover times;

5. The working environment is poor, which is not conducive to on-site management;

6. Insufficient safety protection, which is prone to casualty accidents;

The core problem of machinery manufacturing is cost and efficiency. No matter how you want to do it or how you do it, these two indicators must be better than the average level. Like many industries, regardless of the non-technical levels such as marketing, finance and management, if the technical level does not exceed the average level in cost and efficiency, the enterprise has no way out.

Telephone

Telephone

Products

Products

About DEED

About DEED

Contact US

Contact US